Custom Machining Solutions, Tailored to Your Parts and Objectives

Do you need to machine complex parts, meet tight production rates, and comply with demanding quality standards?

PCI provides machining solutions designed around your production challenges.

Our mission: analyze, design, and integrate the right technologies to turn technical requirements into fully adapted solutions.

Our mission: analyze, design, and integrate the right technologies to turn technical requirements into fully adapted solutions.

A Wide Range of Machining Technologies to Fit Your Needs

As an integrator, our role is to offer the most suitable machining technologies for your industrial environment.

We integrate machine tools from PCI’s own legacy ranges as well as from TTGroup brands (Tongtai, APEC, and Honor Seiki), depending on your technical requirements.

This includes:

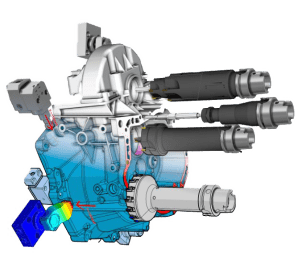

- Horizontal machining centers, including PCI’s METEOR series

- Tongtai vertical machining centers for both standard and complex operations

- Robust Tongtai horizontal lathes for long or complex parts

- Honor Seiki vertical lathes (turret or ATC) for large rotational parts

- High-performance 5-axis gantry machining centers from APEC

Depending on your industrial goals, we select the optimal combination of performance, reliability, flexibility, and total cost of ownership.

Our Machining Process Expertise

Our process engineering team works from your part designs, even the most complex ones, to define a complete and controlled machining cycle:

- Geometric and technological analysis of the parts

- Co-design when needed to improve machinability

- Machining sequencing and cycle time definition

- Design of custom fixtures and cutting tools

- Offline simulation and validation using NC SIMUL

- Commissioning, 3D measurement, and capability analysis (QSSTAT)

- Start-up assistance and production optimization

This expertise, developed through our long-standing experience in the automotive sector, is now applied across a wide range of demanding mechanical industries.

A Machining Solution Designed with a Global Approach

At PCI, we don’t just deliver a machine : we integrate your machining solution into a coherent, automated, and scalable production line, fully adapted to your industrial constraints.

We can integrate:

- Automation systems: robots, part transfers, palletization, supervision

Discover our automation solutions

-

360° services: studies, installation, retrofit, maintenance, and project support

- Retrofit & retooling solutions: modernization, adaptation, or upgrade of your existing equipment

Explore our modernization services

Our mission: to design a cell that’s ready to produce – and ready to evolve.

Our mission: to design a cell that’s ready to produce – and ready to evolve.

A Multi-Sector Approach

Our solutions are designed for all manufacturers with machining needs for simple or complex mechanical parts, across a wide range of industries:

- Mobility (automotive, rail)

- Energy

- Aerospace & space

- Defense & strategic equipment

- General mechanics

Why Choose PCI?

Choosing PCI means partnering with a custom machining expert capable of managing your entire production line.

We combine advanced expertise in process and automation, broad access to machine technologies (from TTGroup), and proven project management capabilities.

As your single point of contact, we coordinate every step with precision – delivering a reliable, consistent solution with no surprises.