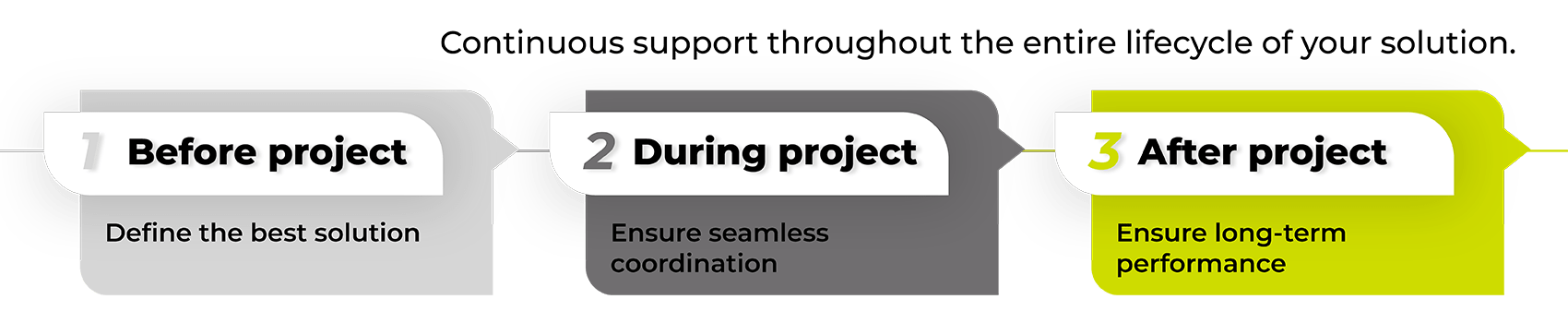

Comprehensive Support Services :

Before, During, and After Your Project

At PCI, our role goes far beyond equipment design. We support your entire production system : from early planning through commissioning, modernization, training, and ongoing technical follow-up.

At PCI, our role goes far beyond equipment design. We support your entire production system : from early planning through commissioning, modernization, training, and ongoing technical follow-up.

Our 360° industrial services are based on a structured project approach, advanced simulation tools, and a strong commitment to close customer support.

Our goal: to ensure sustainable performance, operational control, and the long-term scalability of your production lines — at every stage of their lifecycle.

Our goal: to ensure sustainable performance, operational control, and the long-term scalability of your production lines — at every stage of their lifecycle.

A Full-Service Offering : Before, During, and After Your Project

Our support is based on a global approach led by a dedicated project team.

At each phase (design, implementation, and operation), we provide targeted services to secure your investment, optimize performance, and extend the life of your equipment.

We support you before the project, to define the most suitable solution; during the project, to ensure smooth execution; and after commissioning, to guarantee the continuity and evolution of your production systems.

Before the Project

We carry out all necessary studies to confirm feasibility and precisely size your solution:

- Technical and economic feasibility studies

- Flow simulations, cycle time calculations

- Co-design with your teams (product, ergonomics, layout)

During the Project

Our team manages the entire project in close coordination with yours:

- Full project management (scheduling, safety, subcontractor coordination)

- On-site installation and commissioning

- Operator and technician training

After Commissioning

We remain by your side to ensure lasting performance:

- Preventive and corrective maintenance

- Spare parts stock available at our Saint-Étienne facility

- Fast troubleshooting by our technical teams

- Retrofit and equipment upgrades

- Performance monitoring, technical audits, and system scalability

Retrofit & Retooling: Restoring Value to Your Existing Equipment

Giving your equipment a second life is often faster, more cost-effective, and more sustainable than a full replacement.

At PCI, we support retrofit and retooling projects tailored to your industrial challenge, whether you need to extend a machine’s lifespan, adapt a line to new part references, or integrate new automation functions.

Our expertise covers all the technical building blocks required for successful modernization: mechanics, automation, supervision, safety, and ergonomics.

We work on PCI machines as well as equipment designed by other integrators, ensuring a consistent, reliable, and long-lasting upgrade.

And because effective retrofits often go hand-in-hand with process adjustments or added automation, we draw on our in-house expertise — or guide you toward our complementary solutions, such as custom machining or automation.