PCI Legacy Range : METEOR Horizontal Machining Centers

The METEOR Series: A Legacy of Precision and Reliability

Designed and manufactured by PCI, the horizontal machining centers of the METEOR range have left a lasting mark on high-speed machining, particularly in the automotive sector.

Robust, precise, and proven on thousands of parts, these machines earned the trust of manufacturers seeking long-term reliability and performance.

Today, although the METEOR series is no longer in standard production, PCI continues to provide full support: maintenance, spare parts supply, refurbishment, and retrofit services.

We also remain open to specific projects that may require the development of a new machine based on this trusted range.

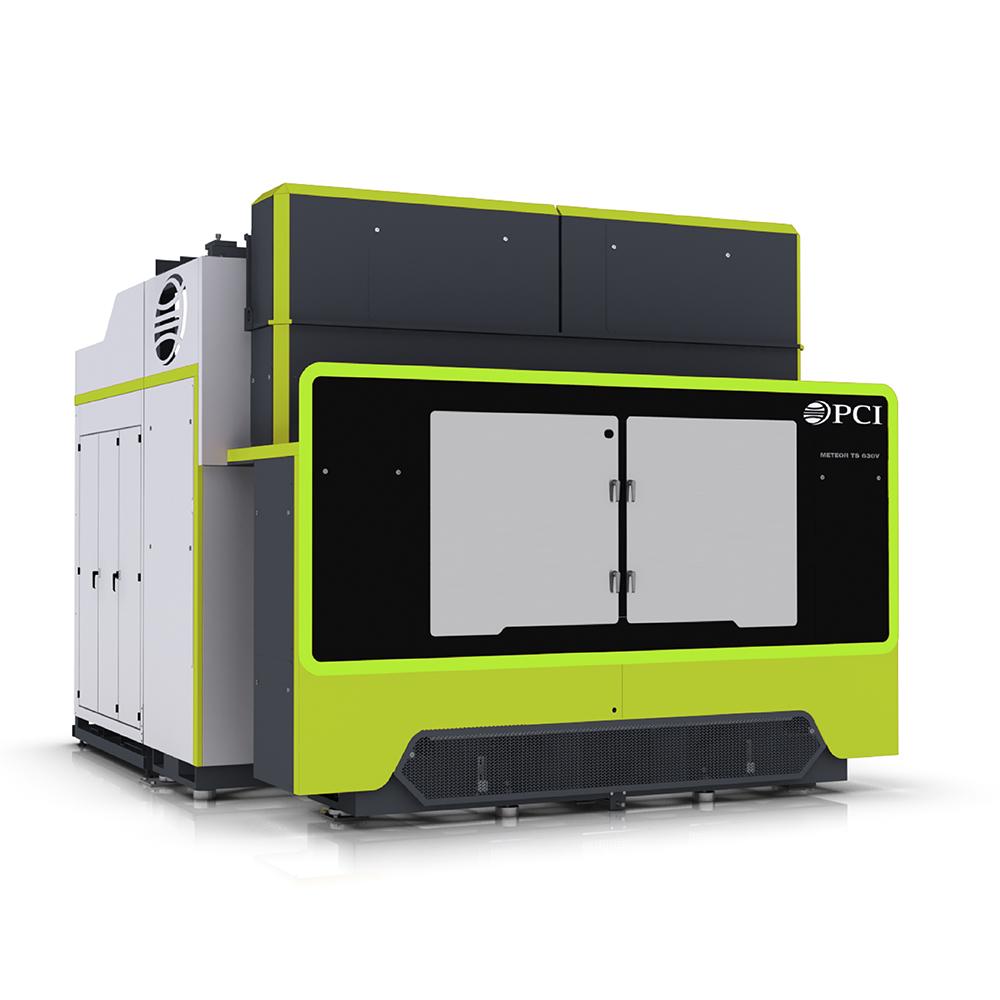

Horizontal machining center

METEOR 630 | 630-P series

Meteor 630 has been developped for the new 2017 range in two different solutions: palletized and non-palletized versions.

Main characteristics

- 4 or 5-axis

- Developed for aluminium treatment

- High speed spindle

Technical data

- Loading methods : Gantry | Palletiser

- X,Y,Z travel : 630/630/630 mm

- X,Y,Z rapid feedrates : 90/80/80 m/min

- Spindle maximum rotation speed : 0-18 000 tr/min

CNC Systems

- Fanuc 31i-B

- Siemens Sinumerik 840 D SL (option)

Horizontal machining center

METEOR 900 | 900-W series

Meteor 900 has been developed in 2019 to complete the 2017 range and exists in two solutions: with or without a W axis.

Main characteristics

- 4 or 5-axis

- Developed for aluminium and cast iron treatment

- HSK100 | HSK63 spindle (optional)

- Optional W axis for large-sized components

Technical data

- Loading methods : Gantry

- X,Y,Z | W travel 900/800/630 | 630 mm

- X,Y,Z | W rapid feedrates : 70/60/80 | 80 m/min

- Spindle maximum rotation speed : 0-12 000 | 0-18 000 tr/min

CNC Systems

- Fanuc 31i-B

- Siemens Sinumerik 840 D SL (option)

Download the METEOR 900 brochure

Horizontal machining center

SÉRIE METEOR 1800 | 1800-P

Meteor 1800 has been developped for the new 2017 range in two different solutions: palletized and non-palletized versions.

Main characteristics

- 4 or 5-axis

- Developed for aluminium treatment

- High speed spindle

Technical data

- Loading methods : Gantry | Palletiser

- X,Y,Z travel : 1800/630/630 mm

- X,Y,Z rapid feedrates : 90/80/80 m/min

- Spindle maximum rotation speed : 0-18 000 tr/min

CNC Systems

- Fanuc 31i-B

- Siemens Sinumerik 840 D SL (option)